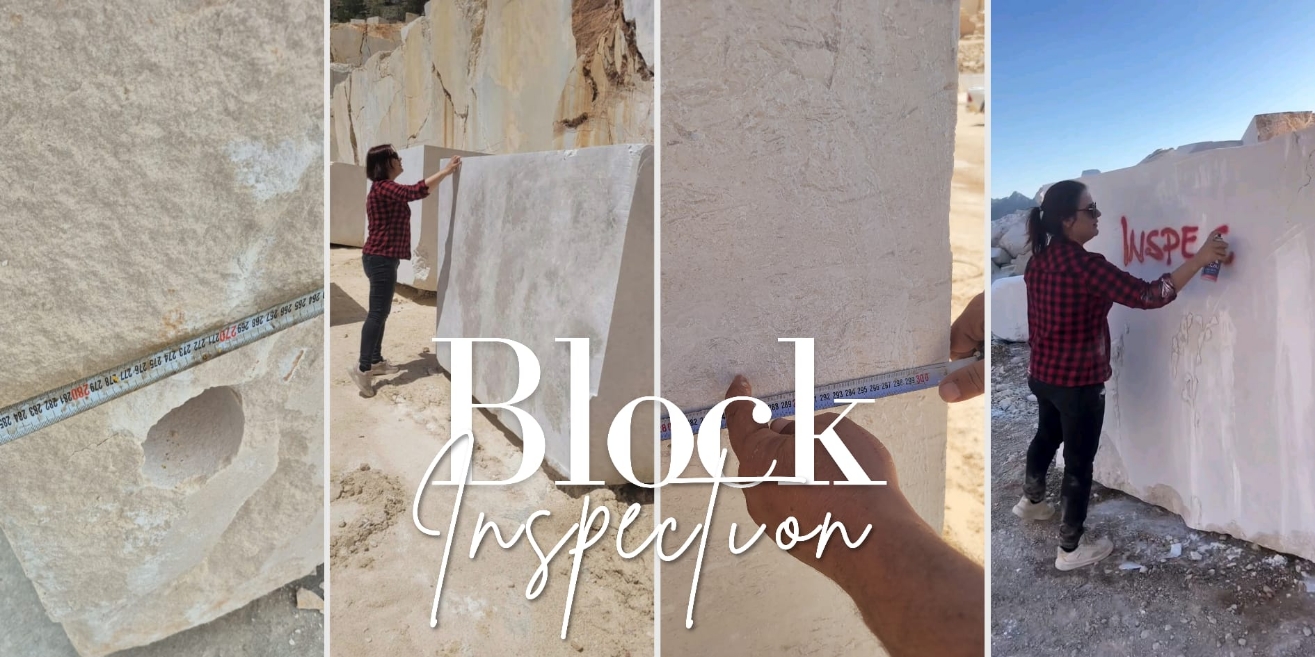

For blocks inspections, the following steps are usually taken into consideration:

Color characteristic and homogeneity

Crack structure

Porosity percentage

Dimensions according to customer expectation

RSS

Blog posts of '2025' 'June'

In terms of slabs, good well reputed suppliers usually inspect slab orders piece by piece at the end of production before packing. They pay close attention to the following points during the slab inspection:

Selection

Polishing quality

Cracks, repairing quality on surface

Slab measurement

Epoxy quality (in order to prevent color changing)

Epoxy and net application quality

Bundle/packing quality

Supplier usually sends the photos of each slab or bundles to our customers with detailed report for the approval before shipment.

Each order is inspected carefully and individually per each crate by our experienced experts to prevent any problems such as: broken corners, cracks, calibration, filling-repairing quality and color selection.

After the quality control operation, following services can be given to the customers:

Sending the photos of 15%- 20% tiles in each crate

Providing the photos of general selection of each container

Suggesting the photos of rejected and separated tiles

Quality control reports

Search

ALL

- 2025